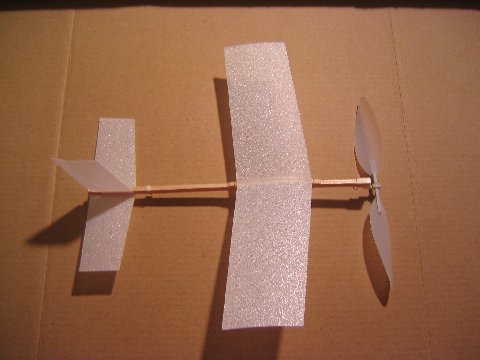

Here’s a neat plane Gary sent me:

Here’s a neat plane Gary sent me:

“This is an AMA Cub reduced in proportion to a 100 mm propeller and made of foam. It is too heavy to fly in the living room, which was the design goal. Neither Lou nor Michael have been able to get theirs flying. I know why. It is way too heavy. Mine is a couple grams lighter than theirs and it barely fits when everything is just right, but circles downward. More power spirals in faster. Left aileron roll levels the wings and climbs, but hits the wall. It is also hair’s breadth sensitive on the controls.

It has been a bit windy for outdoor flights. I want to get the tailplane incidence sorted out. I have some ideas on that and outdoor testing might work if the air is calm. Usually you can’t tell the results of an adjustment outdoors because what it does might have been a result of uneven air, not the adjustment.”

I asked:

Why is it so heavy? What does it weigh? What about cutting circles in the wings and cover the holes with tissue? What about scraping the propeller? What about a smaller stick?

He replies:

I have tables of weights of every part on each plane that I have made, both before and after construction. Here is what I have for Tiny Thom:

Design weight estimate:

1. 0.020″ steel wire prop shaft 0.040 gram

2. 100 mm red plastic prop 0.717

3. P-P prop hanger/bearing 0.180

4. P-P motor hook 0.046

5. 3 mm x 6 mm, 11# stick 0.620

6. Depron wing 1.553

7. Hold down spar, 11# 0.117

8. 2 dental bands 0.003

9. Durobatics tailplane 0.256

10. Durobatics fin/rudder 0.174

Total 3.706 grams

Finished assemblies:

Propeller; 1, 2 and 3 0.976 vs 0.937, 0.039 high

Wing; 6 and 7 1.909 vs 1.670, 0.239 high

Stick; 5, 8, 9 and 10 1.086 vs 1.099 , 0.013 low

Total 3.971 vs 3.706, 0.265 high

I used 0.025″ wire for the prop shaft. The wing is overweight because the hold-down spar was more like 14# wood (0.148, adds 0.031) and there is a long, thick run of glue in the dihedral break/hold-down join (apparently about 0.208).

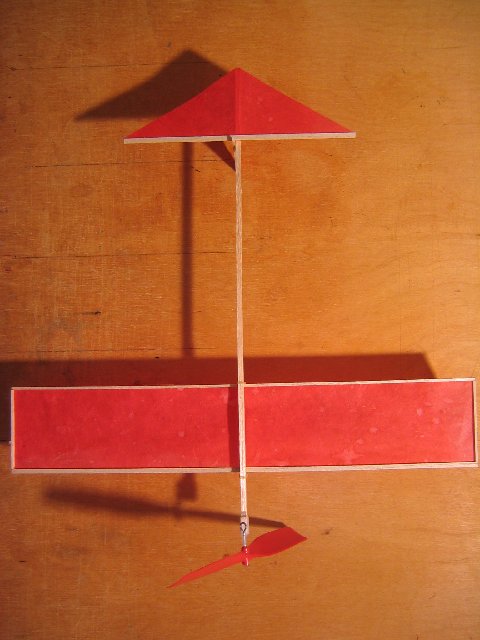

One of the design goals was simplicity. Use of a built up T, I-beam or box is outside that goal. I have another plane, the Moth, that comes in at 2.595 grams, does 21 3/4 circuits in 1:21.13 in the gym and has flown 7 1/2 circuits in 28 seconds inside the 11′ living room.

The only problem with this plane is that the 0.57 mm foam is a bit delicate for kids.

Have you seen the Ikara Butterfly and Kolibri?

Darcy: So if the Ikara Butterfly weighs less than 3g, and your Moth flies well at 2.595 grams, then assuming you have similar wing area on your Tiny Thom, I guess you need to loose like a gram.

Does that make sense?

How thick is that wing material? What if you cut triangles into it and covered with tissue triangles?

I wonder if there’s a way of getting a couple of 10ths off that motor stick.

Gary: Yes, losing a gram would help.

The wing is Depron foam that is 1.36 mm thick and weighs 6.97 gm/100 sqin. The foam in the Ikara Kolibri is 0.33 mm thick and weighs 3.65 gm/100 sqin. The tail is Durobatics foam that is 0.77 mm thick and weighs 2.35 gm/100 sqin, but is too flimsy for the wing. It is fuzzy on one side and soft, so it is hard to reliably measure its thickness. It is marginal on the tail. It works OK in the Moth because the moth has 8.3% camber that stiffens it. Kolibri foam would help, but would be used on the tail as well. There is another foam that is a little thicker that might be better in stiffness for this wing. The economies of the diecut process require that all surfaces be cut from the same sheet.

The intent of this design is that it be a quick clip together that a 10 year old can make in 5 minutes and then it will fly reliably in the house.

The motor stick could be thinner. The other guys are using 1/8″ square. (They call their plane “Wee Thomas”.) But that requires a nose block so the stick can fit in the prop bearing and there isn’t room for the tailplane taper.

I will be going over all the weights again tonight to see whether I can save enough to justify building another plane. I am thinking of a Moth with a 1/16″ x 1/8″ stick.

I just remembered, I can’t get the prop assembly any lighter. Or not by much, anyway. All the parts are off the shelf. I could scrape the prop a little, but that isn’t going to help much and we can’t expect kids to scrape a prop with a razor blade. That limits how much weight we can take off everything else. The wing is already jammed up against the prop hanger. Taking more weight off everything else will move the CG forward into dive location. It might be possible to take weight off the wing, add weight to the tail and have the whole thing lighter without moving the CG. That is a more complex calculation, might be worth doing. Then there is the problem that the production version is intended to use a heavy plastic wing clip, 1.1 gram itself, instead of the balsa stick and two dental rubber bands.

I think we have painted ourselves into a corner. I think we must start over.